Tuning a PID controller can be difficult knowing where to start, and what direction to go. This article will provide solutions to both of these, setting up a PID controller from scratch and more! To start, read “ PID Controller Explained“, to learn what a PID controller is and how it works. PID controllers often provide acceptable control using default tunings, but performance can generally be improved by careful tuning , and performance may be unacceptable with poor tuning.

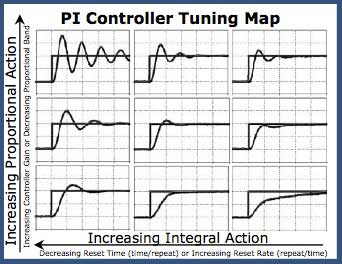

Usually, initial designs need to be adjusted repeatedly through computer simulations until the closed-loop system performs or compromises as desired. The goal of tuning a PID loop is to make it stable, responsive and to minimize overshooting. These goals – especially the last two – conflict with each other. You must find a compromise between the goals which acceptably satisfies them all.

PID Tuning by Commercial PID. If you have access to a PID controller unit and a compatible thermal probe that fits down into your hoten you can use them to tune your PID and calibrate your thermistor. These work by applying a step change to the system and observing the resulting response. The first method entails measuring the lag or delay in response and then the time is taken to reach the new output value. So before dealing with any real-time PID controllers, or PID control algorithms in any controller like PLCs or PACs, first we have to consider the type of equation used for implementing PID control function, before we go through its tuning process.

The three main reasons of PID controller to become an important control include an earlier record. This parameter can also be called Proportional Band and measured in the unit of percent. PID controller is the most widely used technology in industry for the control of business-critical production processes and it is seemingly here to stay. This guide offers a ―best-practices‖ approach to PID controller tuning.

What is meant by a ―best-practices‖ approach? In applying loop tuning to a cascade control confi guration, you need to tune one loop at a time due to interaction of inner loop dynamics on the outer loop. Note that the inner loop must be tuned fi rst before tuning the outer loop unless using a one-shot cascade tuning tool.

Put the outer loop in Manual. PID autotuning lets you tune a PID controller in real time against a physical plant. Your quad is controlled by what is known as a “ PID loop”. In this short tutorial I will take you through the two Ziegler-Nichols tuning methods.

This will let you tune the derivative, proportional and integral gains. PID tuning is completely free. Take the PID loop tuning (Instrumentation and Process Control) worksheet. Use this free PID controller tune software to import your data, visualize your data in graphs, obtain a precise process system model and the free pid gains tune algorithm to obtain the optimal pid gains for your plant system. Starting with firmware version 2. Follow these steps: Once you open the PID calibration menu, set the temperature at which the calibration should run.

The appropriate tuning parameters can be computed from these two values according to the following rules: Caveats. Unfortunately, PID loop tuning isn’t really that simple. Different PID controllers use different versions of the PID formula, and each must be tuned according to the appropriate set of rules.

This point report discusses realisation and tuning of software based PID -controllers. The intended reader is an engineer that is interested in how a PID -controller is implemented and tuned with the AMIGO (Approximate M-constrained integral gain optimization) method. All mathematical reasoning is explained in detail step by step. PID-regulator är en ofta använd regulator inom reglertekniken.

Förkortningen PID kommer från regulatorns tre element: en proportionerlig del, en integrerande del samt en deriverande del. Basically, this guide shares a simplified and repeatable procedure for analyzing the dynamics of a process and for determining appropriate model and tuning parameters. Classic PID Kp: 39. You will see one last set of numbers. The values you are looking for are Kp, Ki, and Kd.

Write these values down, they will be your new PID values. You can use the EEPROM menu to enter these values to the Ext1. Eastman Chemical ). Tuning thermal PID loops When dealing with critical temperature applications, PID controllers are a common regulatory approach, but tuning these often requires a different strategy than other types of loops.

Auto- tuning features can help if you understand them.

Inga kommentarer:

Skicka en kommentar